PTAC Energy Saver is pleased to offer the proven Adaptive Climate Controller (ACC) technology.

ACC is a multi-patented, optical programming device that can dramatically improve the HVAC operating system. Thousands of the devices have been installed around the world to improve all types of HVAC units. including PTACs, Mini Split systems, 1 & 2 stage heat pumps and a/c and air handler split systems.

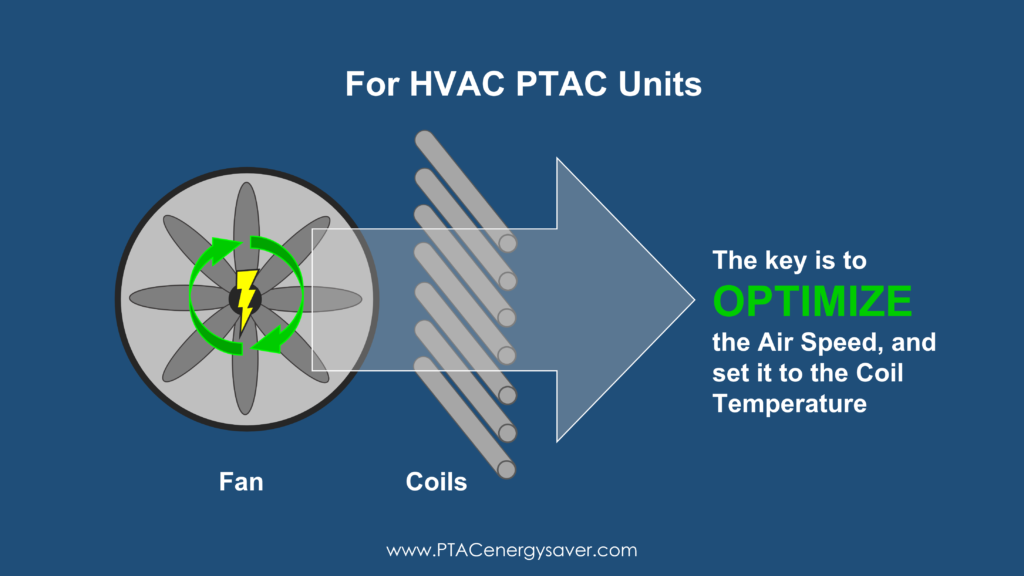

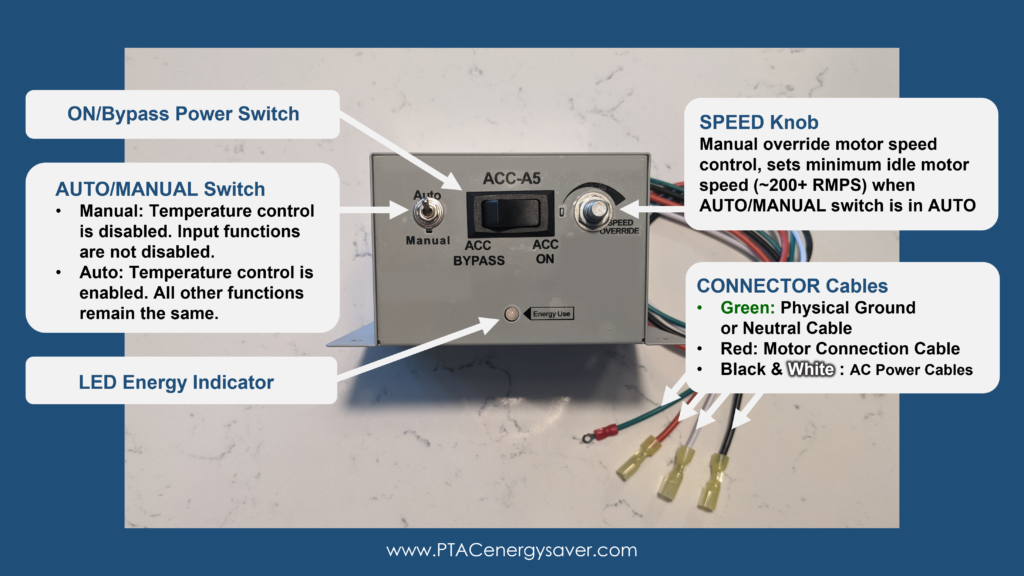

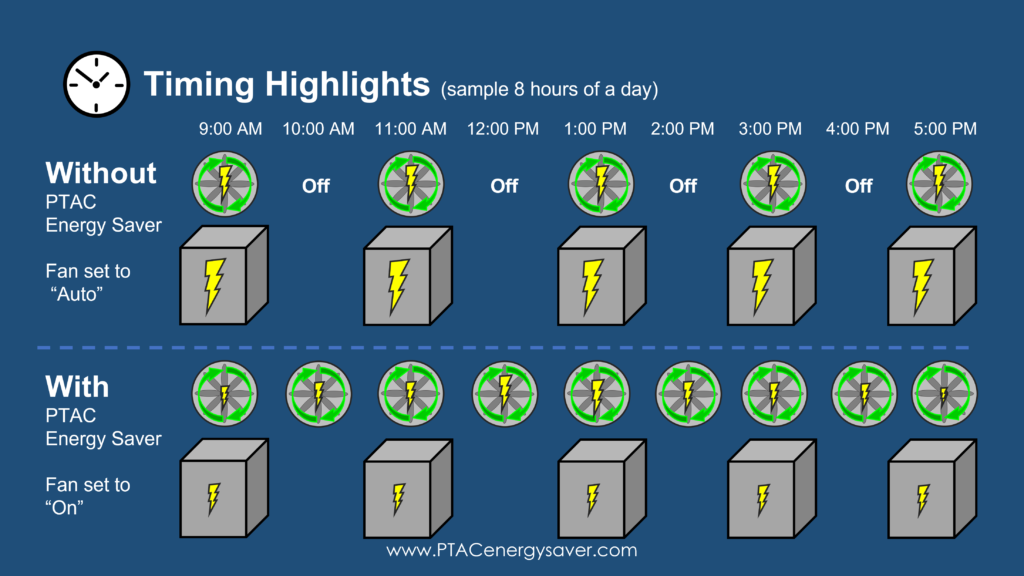

Typically, when an HVAC system turns off, shortly after, the blower fan motor turns off. The ACC reprograms the blower fan not to shut off but to throttle back the rpm airflow to an exceptionally low speed, quiescent level airflow or “idle speed”. This allows for a gentle but continuous air movement into the building that helps keep equilibrium of climate conditions in the occupied space. Rather than static stationary air that creates hot and cold spots along with poorer air quality, this also improves the indoor air quality, air climate and comfort while at the same time reduces energy consumption by a minimum of 30%. The ACC conditions the business’s heating and air conditioning year-round. This is just one benefit of a total of six energy savings benefits.

Additional Benefits:

- Soft Start Feature – A motor start current is softened substantially which lowers the demand charges, charged by Power Companies.

- Anti-Stall – AC motors get power from the grid which varies voltage/power significantly throughout the day’s demand. To overcome this variability and avoid stalling, most motors are designed to provide more power than required. The ACC with its optical programming constantly delivers the right amount of power at any given time thus saving kilowatts twenty-four hours a day.

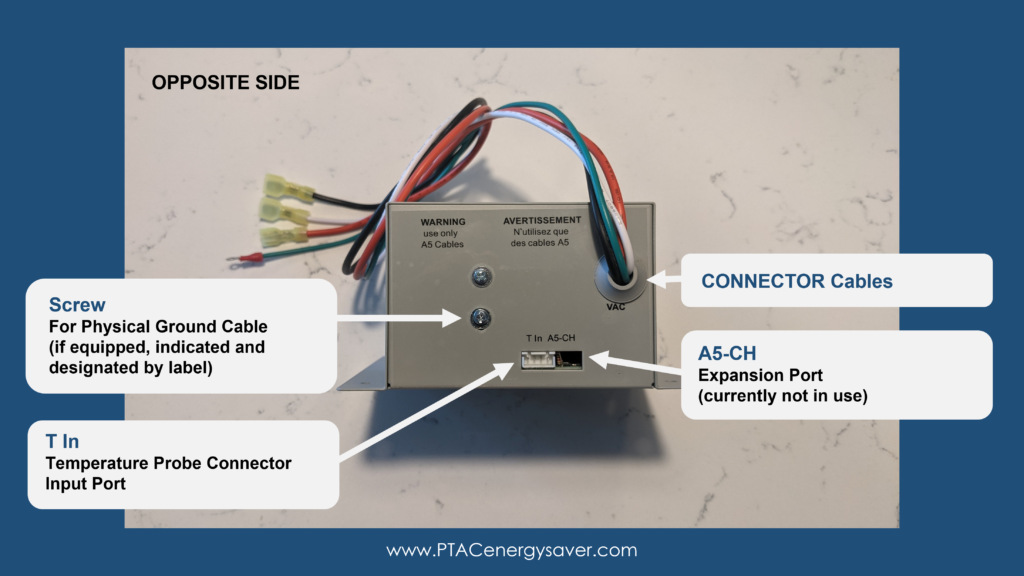

- Temperature and Humidity Control – This “key” benefit is real time output temperature and humidity tracking and resultant motor fan control. By monitoring both temperature and humidity with sensors, it adjusts the fan speed for changes detected in the system output air, for heating and cooling. This removes the heat and humidity much quicker inside the building. The result is the HVAC run time is shorten dramatically to reach the set-back temperature on the thermostat.

- Analog vs Digital PWM Inverters for motors – Most AC motors, like the Grid, are analog in design, yet most motor controllers today are digital in design which try to force the analog motor to accept digital power known as PWN or Pulse Width Modulated. The ACC is analog in design which is a lot friendlier to single phase AC motor and avoids many of the challenges and stress problems to motors that are found in all types of digital PWN inverters.

- ASD vs VFD – The AMC is an “adaptive speed drive” and a VFD is “variable frequency drive.” VFD’s have been used on motors for years. The main benefit of a VFD is that it reduces energy costs by delivering variable speed power. The biggest negative! It distorts the power’s sinewave, adds noise, harmonics (heat) which shortens the life span of all sizes of AC motors. The ACC does the opposite, it cleans the sign wave, eliminates noise and harmonics. The results: motors last longer, and run cooler, smoother and quieter while cutting kilowatt usage and lowering demand charges.

PRESENTATION FILE:

If you would like to review the complete 49 page presentation Contact Us, and we will email the PDF slide deck to you. You can also learn more by watching the 5 minute “How it Works PTAC Video“

Please see some of the highlight slides below.